3つの強み

半世紀以上にわたりプラスチック成形加工のリーディングカンパニーであり続けている天馬には3つの強みがあります。

自社製品と受注製品。

2つのピラー

自社製品で培った開発力と受注製品で磨いた技術力で、高い付加価値を提供しています。

多くのプラスチック成形メーカーは、自社製品か受注製品のどちらか一方を扱っています。それに対して当社は、自社製品と受注製品の両方を取り扱っていることが大きな特徴です。

人々の生活に密着した自社製品

日本国内では自社製品を中心に製造しています。お客様に心から喜んでいただくことを目指し、収納ケースやキッチン用品、バス用品など、使い勝手にとことんこだわった幅広い家庭用品の開発に努めています。

なかでも豊富なラインナップを用意している「フィッツケース」は、累計販売数1億個を突破する人気ブランドとして、多くの方々から愛されています。

受託製造品

当社はOA機器部品製造、自動車部品製造、家電部品製造、住設部品製造、メディアケース製造等、幅広い分野の製造実績があり、長年蓄積したノウハウを生かし、お客様のあらゆるニーズにお応えします。

射出成形のみならず、「異素材からの樹脂化」・「OEM生産」・「設計開発から量産までの一貫生産」等の様々なご提案が可能です。幅広い分野の製造実績と、そこで培ったメーカーとしての視点や発想をもとに、受託製造品においても付加価値の⾼い提案を提供しております。

世界中に届ける「高品質」

国内外を問わず、統一された技術基準のもと高品質の製品を製造しています。

天馬では国内6工場、海外の11生産拠点のすべてにおいて、統一された技術水準のもとで生産を行っています。そのため国内、海外を問わず、常に同一で高品質の製品を製造・供給できるのです。

「メーカーにとって最も大事なのは品質である」。私どもは創業時から、その想いのもと、品質には徹底的にこだわってきました。社員一人ひとりが品質への高い意識を持つため、生産性分野、設備管理、金型管理、作業者及びマネジメント教育などの各項目に基準を設定。各工場の品質保証課や技術部による定期的な品質監査で、その基準が満たされているかどうかを念入りにチェックしています。

お客様から製品へのご意見があった際は、その要因を徹底分析し、ひとつひとつ着実に解決してきました。その積み重ねが、現在のお客様からの高い信頼に結びついています。国内ではISO9001、海外ではISO9001に加えてISO14001も取得(一部地域を除く)するなど、マネジメント力の強化と環境への配慮にも注力しています。さらに現在、ロボットやAI画像認識技術を活用した工場の自動化を推進しています。それにより、不具合品の発生や人為的なミスを減らし、さらなる品質の向上を目指しています。

グローバルネットワーク

アジアに広がる信頼度の高いサプライチェーンを土台に、グローバル事業を推進しています。

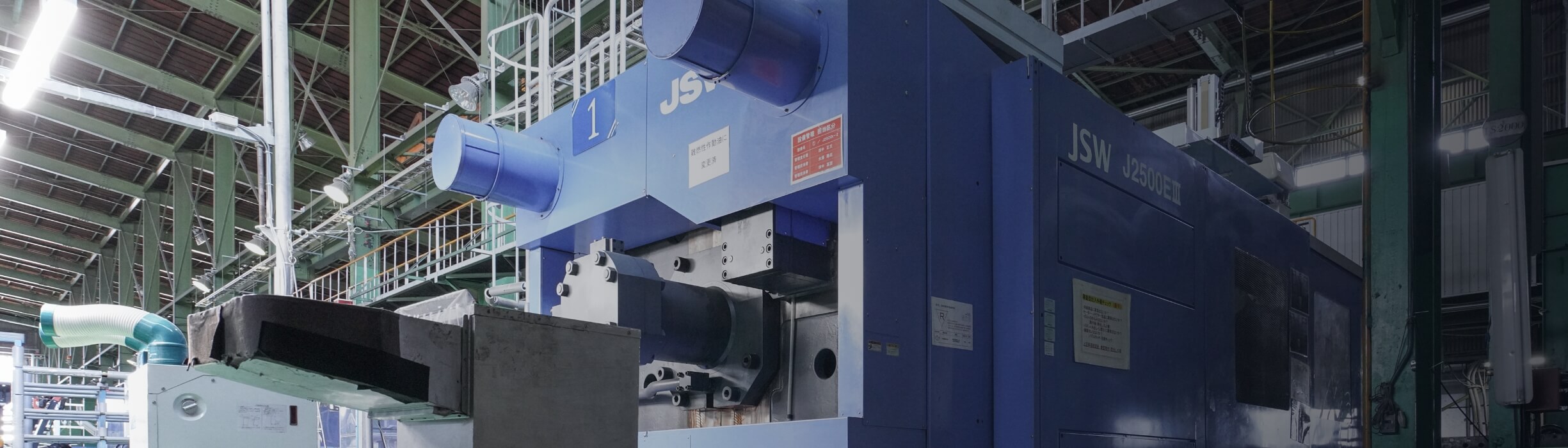

天馬はアジアに11の生産拠点をもち、グループで1000台以上の成形機を所有しています。そのような充実したネットワークとインフラによる商品供給力で、お取引先のグローバルな調達戦略ニーズにお応えしてきました。その信頼度の高いサプライチェーンは、お客様から高く評価されています。

現在、中国には上海、深圳、中山の3拠点があります。深圳や中山はOA関連の受託製造が中心ですが、上海では自社製品をメインで製造しています。ベトナムにはハノイに2拠点、ホーチミン郊外に1拠点あり、OAや家電の受託製造をしています。さらにタイの2拠点(ラヨーン県、プラチンブリ県)ではOAや空調関連の受託製造、インドネシアの3拠点(ブカシ市、カラワン県) では車両やOA関連の受託製造をしています。2022年からはインドネシアで自社製品の製造・販売をスタートし、タイやベトナムでも自社製品の製造を予定しています。

これら当社の海外拠点では、8000人以上の社員が働いています。海外拠点の社員は基本的に現地採用しており、そのなかから幹部を育成しています。すでに進出して20年以上が経つ中国では、多くの幹部社員が育っています。管理職のうち女性が20%以上を占めるなど、女性比率が高いのも当社の海外拠点の特徴です。このようなアジア5ヵ国に広がる人材のネットワークも、天馬の大きな強みです。